You've heard of the latest and greatest in sustainability: bamboo. It's a big hit on the list of renewable resources. Bamboo is said to be one of the most sustainable plants to produce from because it:

- Grows quickly and abundantly.

- Requires minimal water and labor.

- Is naturally pest-resistant and does not require pesticides and herbicides.

Photo of Bamboo by Jakob Owens on Unsplash

And yet, while these are all truths about bamboo, many modern day production practices have transformed the fiber into something else entirely in order to greenwash the finished product. I, personally, am tired of falling victim to greenwashing scams, and was skeptical of bamboo products. So I did some research.

Bamboo is a bast fiber, much like hemp and linen. Without intense processing, bamboo makes for a very sustainable building material due to its strength and durability. It is suitable for flooring, furniture, construction materials, and is an eco-conscious substitute for just about anything made from wood.

Photo of Bamboo by Aldric RIVAT on Unsplash

But these days, bamboo is used to make anything and everything, including fabric for clothing and bedding. Imagine making a t-shirt out of wood. Seems impossible, right? Or at least extremely uncomfortable. That's because bamboo is not meant for these applications. In nature, bamboo stalks are not soft, flexible, and stretchy like you t-shirt. They are thick, coarse, and structured. So what is bamboo fabric? How is it made? And is it really sustainable?

Bamboo fabric is produced using one of two methods:

- Mechanical. "This involves crushing the plants into a mush, using natural enzymes to break it down and then combing out the fibres and spinning them into a yarn." [1] This method is very labor-intensive and expensive. The end product is not soft enough to be worn as clothing.

- Chemical. "The plants are cooked in a cocktail of chemical solvents - primarily sodium hydroxide (lye, or caustic soda, as it's more commonly known) and carbon disulfide. Both are known to be harmful to human health, and sodium hydroxide can harm aquatic life when released into the water supply." [1] This process exposes both workers and consumers to harsh chemicals and heavy metals throughout the life of the product.

Photo of Floating Bamboo by Lennart Heim on Unsplash

If you're still unsure, think about how bamboo was used before the age of the Machine and the Chemical. If your ancestors were able to make soft, stretchy t-shirt fabric out of bamboo, then you could be reasonable confident that it's sustainable. But the truth is, they couldn't have. Bamboo does not simply transform into fabric. You must use machinery and chemicals to boil the fiber down into something it's not. Your bamboo t-shirt is, essentially, a rayon (viscose) fiber.

According to the Federal Trade Commission, "Rayon is a man-made fiber created from the cellulose found in plants and trees and processed with a harsh chemical that releases hazardous air pollutants. Any plant or tree could be used as the cellulose source—including bamboo—but the fiber that is created is rayon." [2]

I'd also like to point out that you will never be able to find a certified article of bamboo clothing. According to The Soil Association, the production processes required to manufacture bamboo fabric does not comply with their standards [1].

Don't get me wrong - the fact remains that bamboo is a great resource for building materials, and makes for an incomparable renewable and sustainable alternative to wood (save a tree!). But your ancestors could have told you that one.

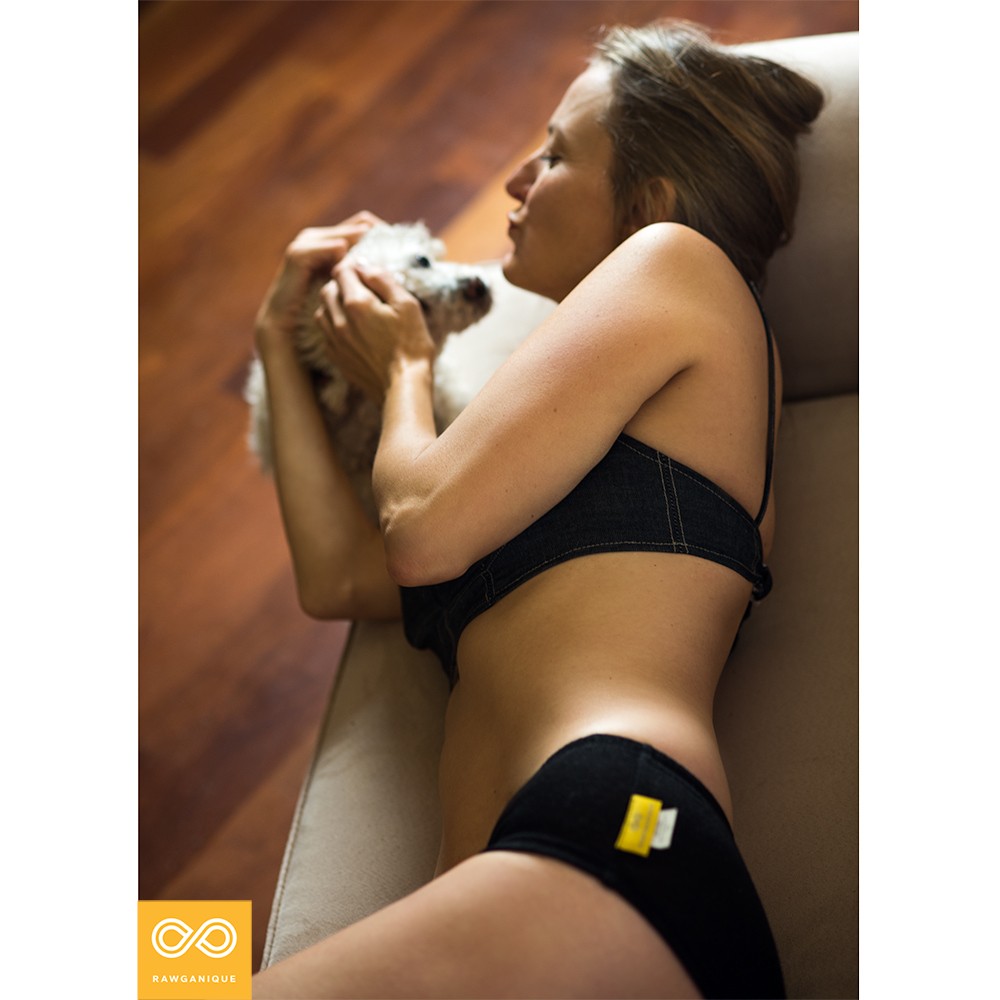

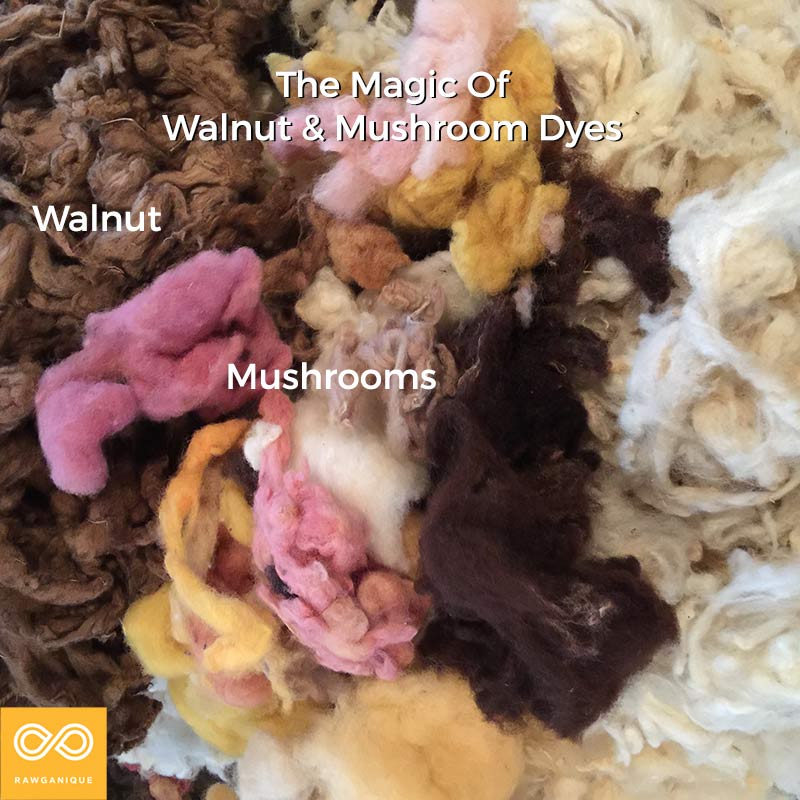

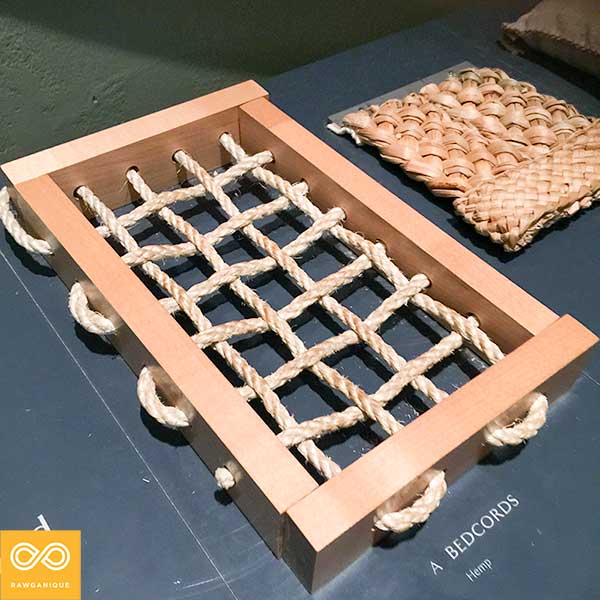

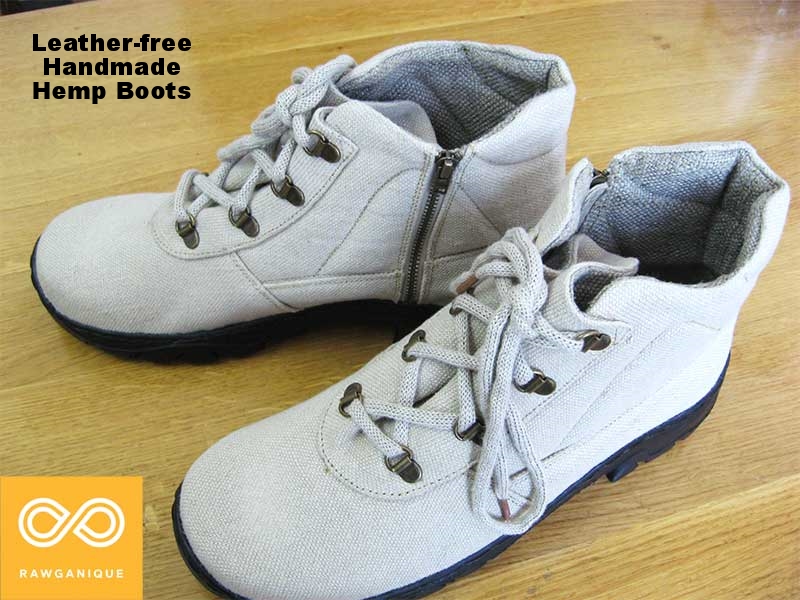

In sum, if you're going for eco-conscious clothing, bedding and bath products, stay away from bamboo. We recommend shopping for 100% organic cotton, linen, and hemp products. Like bamboo, these fibers grow quickly and abundantly, and if done properly, do not require pesticides and herbicides. These are materials that can and have been certified, and can also be transformed into soft, delicate fabrics. For proof, take a look at Rawganique's products. We sell organic products to suit every need, and they are made sweatshop-free and chemical-free during all stages of the production process. These are products you can rely on.

Sources: